1

Products Description

The Machino coupling is a type of hose coupling commonly used in firefighting and is especially popular in Japan. Its unique design and functionality distinguish it from other types of hose couplings, such as the Storz coupling. Here is an in-depth look at the Machino coupling:

- Design Characteristics:

- Type: The Machino coupling is a quick-connect/disconnect coupling used primarily for fire hoses.

- Material: Typically, these couplings are made from aluminum, which provides a lightweight yet sturdy construction. Aluminum is chosen for its resistance to corrosion and its durability.

- Male and Female Parts: Unlike symmetrical couplings like Storz, Machino couplings have distinct male and female parts. The male part has a smooth cylindrical shape with external ribs, while the female part has corresponding internal grooves.

- Connection Mechanism:

- Hook and Latch System: To connect, the female part of the coupling is slid onto the male part, and a simple hook and latch system is used to secure the connection.

- Gasket Seal: A gasket within the female part ensures a tight and leak-free connection when the coupling is locked.

- Sizes and Customization:

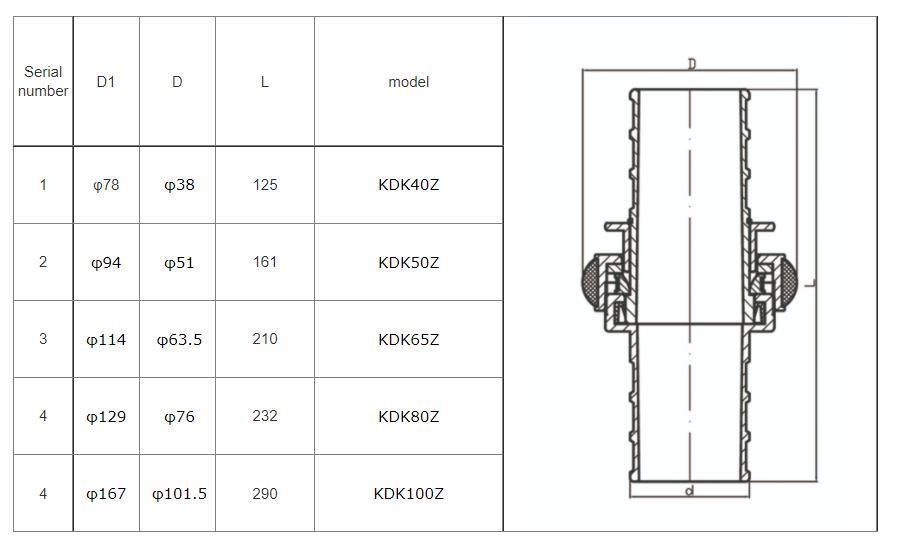

- Standard Sizes: Machino couplings come in several standard sizes to fit different hose diameters.

- Customization: Like the Storz coupling, Machino couplings can be customized for different hose sizes and lengths, catering to specific requirements.

- Manufacturing Process:

- Casting and Forging: Similar to Storz couplings, Machino couplings can be made using casting or forging processes. The choice of process depends on the required strength and the complexity of the design.

- Applications:

- Firefighting: Predominantly used in firefighting, especially in Japan and some parts of Asia.

- Industrial Use: Also used in industrial settings for water transport and in applications requiring quick hose connections.

- Advantages:

- Quick and Secure Connection: The design allows for a rapid connection which is essential in emergency situations like firefighting.

- Lightweight and Durable: The aluminum construction makes it easy to handle yet robust enough for harsh environments.

- Corrosion Resistant: Ideal for use in scenarios where the coupling is exposed to water and other corrosive substances.

- Quality Standards:

- Compliance with Safety Standards: These couplings adhere to specific safety and quality standards to ensure reliability in high-pressure and emergency situations.

- Maintenance and Durability:

- Easy to Maintain: The simplicity of the design makes Machino couplings easy to inspect, clean, and maintain.

- Long-Lasting: With proper maintenance, these couplings have a long service life.

- Global Adoption:

- While most popular in Japan, Machino couplings are recognized and used in various parts of the world due to their specific advantages in firefighting applications.

This detailed analysis provides a comprehensive overview of the Machino coupling, emphasizing its design, functionality, and application in firefighting and industrial contexts.

How to use Machino couplings?

Using Machino couplings involves several steps to ensure a secure and efficient connection for fire hoses or industrial applications. Here’s a detailed guide on how to use Machino couplings:

- Preparation:

- Inspect the Couplings: Before use, check both the male and female parts for any damage, debris, or wear that might affect the performance.

- Check the Gasket: Ensure the gasket on the female part is in good condition to prevent leaks.

- Connecting the Couplings:

- Align the Male and Female Parts: Hold the hose with the male part in one hand and the hose with the female part in the other. Align the male part’s ribs with the grooves inside the female part.

- Insertion: Gently insert the male part into the female part, ensuring it’s inserted straight to avoid cross-threading or damage.

- Locking Mechanism: Once the male part is fully inserted, lock the coupling by engaging the hook and latch system. This usually involves pushing or sliding a collar on the female part until it snaps or clicks into place, securing the male part.

- Testing the Connection:

- Visual Inspection: Look at the connection to ensure it’s fully engaged and there are no visible gaps.

- Test for Leaks: Once connected, gradually increase the water pressure to check for leaks. A properly connected Machino coupling should not leak.

- Using the Coupling:

- Operate as Needed: With the hoses connected, proceed with the operation, whether it’s firefighting, irrigation, or any other application.

- Monitoring: Continually monitor the connection and hose during use, especially in high-pressure situations, to ensure the coupling remains secure and leak-free.

- Disconnecting the Couplings:

- Reduce Pressure: Before disconnecting, ensure that the pressure in the hose is reduced or turned off to prevent injury or damage.

- Unlocking: Release the locking mechanism on the female part, usually by pulling or sliding the collar away from the male part.

- Separation: Once unlocked, gently pull the male and female parts apart. Avoid twisting or jerking the hoses, as this can damage the coupling or the hose.

- Post-Use Care:

- Inspection: After disconnection, inspect the couplings again for any damage or wear.

- Cleaning: Clean any debris or residue from the couplings to ensure they’re ready for next use. This might involve rinsing with water or using a brush to remove dirt.

- Storage: Store the couplings in a dry and clean environment. Proper storage will prevent damage to the locking mechanism and ensure the longevity of the gasket and the coupling itself.

- Maintenance:

- Regular Checks: Regularly inspect the couplings for any signs of corrosion, wear, or damage.

- Gasket Replacement: Replace the gasket as needed to ensure a tight seal. This is often the part that wears out first.

- Lubrication: Occasionally, the locking mechanism might require lubrication to ensure smooth operation. Use a suitable lubricant that doesn’t degrade the material of the coupling or the gasket.

By following these steps, you can effectively use Machino couplings for various applications, ensuring a secure, efficient, and leak-free connection. As with any equipment used in critical applications like firefighting or industrial processes, proper training and adherence to safety standards are crucial to ensure safe and effective use.

2

Specifications