1

Products Description

The multi-lug hose coupling consists of two or more lugs or locking mechanisms that interlock with corresponding lugs on another coupling or equipment. These lugs are typically arranged in a circular pattern and are used to secure the coupling in place, ensuring a tight and reliable connection.

One of the main features of multi-lug hose couplings is their versatility and compatibility with different hose sizes and types. They are available in various sizes and configurations to accommodate different hose diameters and connection requirements. This allows for easy and convenient connection between hoses of different sizes or to other equipment, such as pumps, valves, or nozzles.

How To Install Multi-lug Hose Coupling:

Operating a multi-lug hose coupling involves a few simple steps to ensure a secure and leak-proof connection. Here is a general guide on how to operate a multi-lug hose coupling:

- Prepare the hoses: Ensure that the hoses you are connecting are clean and free from any debris or dirt. Trim the ends of the hoses if necessary to ensure a clean and even surface for connection.

- Align the coupling lugs: Take the coupling and align the lugs with the corresponding lugs on the other coupling or equipment you are connecting to. Ensure that the lugs are properly aligned to ensure a secure connection.

- Push and rotate: Push the coupling into the other coupling or equipment while simultaneously rotating it. The lugs should interlock and slide smoothly into place. Apply gentle pressure to assist in the connection process.

- Verify the connection: Once the lugs are fully engaged, ensure that the couplings are securely connected. You can give a gentle tug on the hoses to check if the connection is tight and secure. Ensure there is no visible gap between the couplings.

- Lock the coupling: Some multi-lug hose couplings come with a locking mechanism to provide additional security. If your coupling has a locking feature, engage it to prevent accidental disconnection during operation.

- Test the connection: After connecting the hoses, it is recommended to conduct a pressure or leakage test to verify the integrity of the connection. Apply the appropriate pressure or fluid to the hoses and check for any leaks or abnormalities.

- Disconnecting the coupling: To disconnect the multi-lug hose coupling, release any locking mechanisms if present. Hold the hoses firmly and rotate the coupling while pulling it out from the coupling or equipment. Ensure that the pressure is released and that there is no residual fluid in the hoses before disconnecting. It is important to follow any specific instructions provided by the manufacturer of the multi-lug hose coupling, as different couplings may have variations in their operating procedures. Additionally, always adhere to safety precautions and guidelines when working with hoses and fluid transfer systems.

2

Specifications

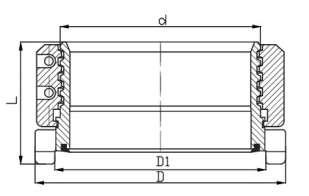

| Pictures | Size | Main Material | ||||

|

D1 | D | L | d | Specs | Material |

| Φ219 | Φ275 | 185 | Φ203 | 8″ | Aluminium Alloy | |

| Φ270 | Φ315 | 176 | Φ253 | 10″ | Aluminium Alloy | |

| Φ320 | Φ380 | 178 | Φ304 | 12″ | Aluminium Alloy | |

| Φ441 | Φ501 | 186 | Φ407 | 14″ | Aluminium Alloy | |

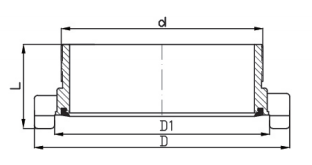

|

D1 | D | L | d | Specs | Material |

| Φ380 | Φ320 | 125 | M300*4 | 12″ | Aluminium Alloy | |

| Φ315 | Φ270 | 100 | M255*4 | 10″ | Aluminium Alloy | |

NAME:XHYXFire Good price casting storz fire hydrant coupling fire hose coupling made in china

1. Application: For fire fighting service and other water related industries, it also comes as standard in tankers and bulk powder systems.

2. Material: The standard material is Aluminum, optional materials of Brass and Stainless Steel available.

3. Pressure: Maximum working pressure is 16 bar

4. Size: 1″ to 6″

Adavantage of Storz Fire Hose Coupling:

Good abrasion resistant, light weight, economical cost;

Save time compared with flanged or threaded fittings;

No tools needed and make the job easy;

Safety sealing for fluids, powders and pellets,Light weight and durable;

Could keep the transfers safe without any damage or any risks.

Q 1::What are the advantages of our factory? A1::Our factory is specialized in manufacturing hose coupling for 30 years,and our promise is to provide our world-class quality, on-time delivery and excellent after-sales services Q2::How about our products? A2::Our products are famous for the good quality and good watering effect,and also you can get the free samples to do a test of the quality and watering effect. Q3::How about hose specifications? A3::We can produce lay flat hose according to your request on Inner Diameter, working pressure,color and length per roll. Before send you right quotation, please kindly confirm with us. Q4::How about get the samples? A4::You can get the samples for freejust pay for the sample freight.We will set it by DHL,FEDEX,UPS,TNT,EMS. Q5::What is the minimum order quantity?(MOQ) A5::Usually our MOQ is 3000 pieces, but for first cooperation we also accept little order, so any order is welcomed. Q6::How about delivery ? A6::We can send to you by sea/air/express according to you, usually deliver within 7-10 working days after receive deposit.